- Seiko Future Creation Inc.

- About Us

About Us

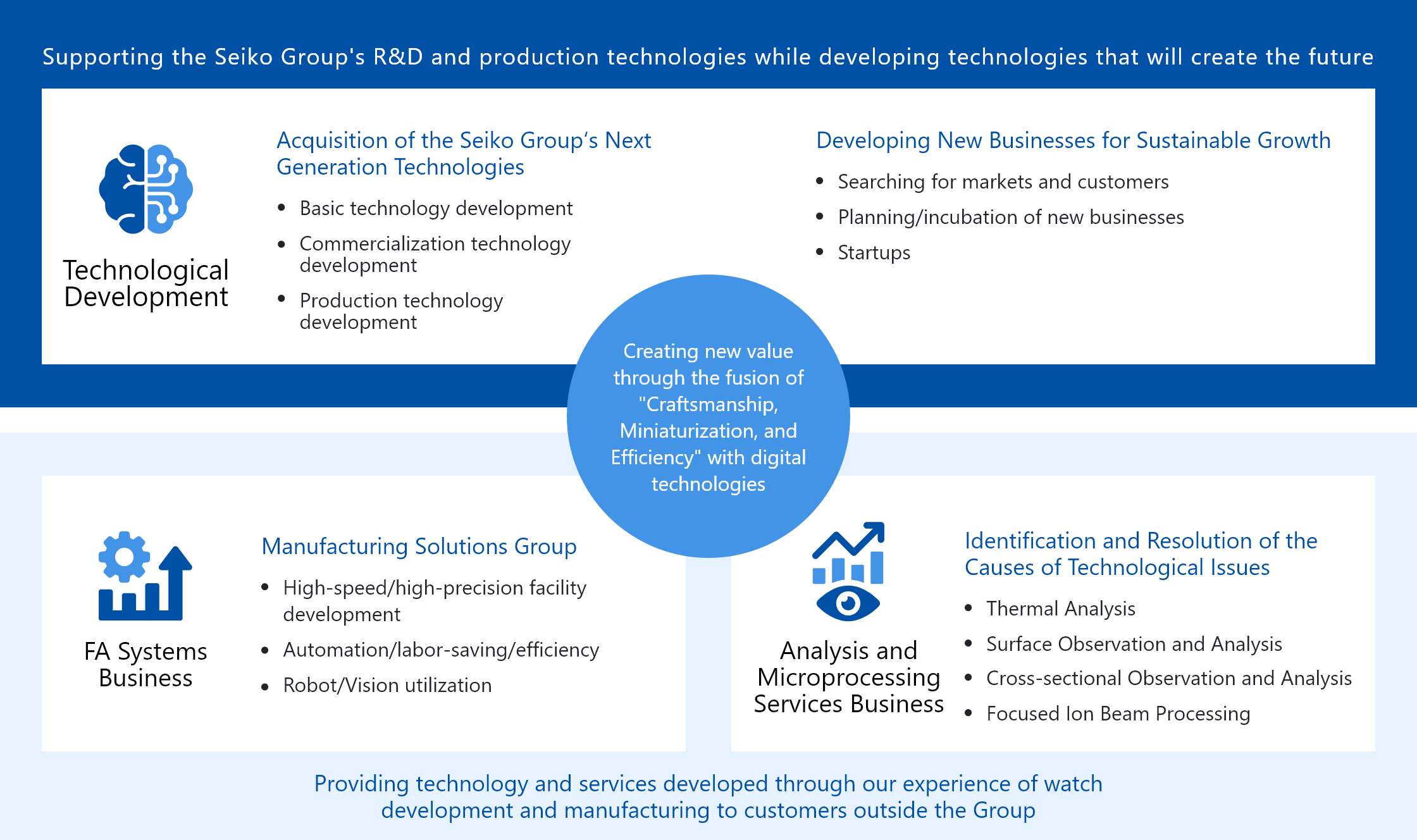

Seiko Future Creation Inc. was established in July 2022 through the integration of the Seiko Group Corporation R&D division and Seiko I Techno Research Co., Ltd., which handled instrumental analysis.

Seiko Future Creation Inc. has two main missions.

One is to support the Seiko Group's manufacturing as the organization responsible for its R&D and production technologies.

The other is to provide valuable products and services developed through our experience of watch development and manufacturing to customers outside the Group.

By integrating the divisions involved in technology development and R&D into a mutually linked development structure, we will be able to realize speedy business operations capable of responding to future change with prompt decision-making and swift practical application of results. We will tackle the challenge of creating new social value with our drive to "create the future," enriched by technology.

Technological Development

The Technological Development division of Seiko Future Creation will develop the basic and production technologies that support the Seiko Group's manufacturing, as well as develop the Group's technological domains and create new business opportunities.

Today, watches are no longer exclusively tools for tracking the time—they are becoming items that appeal to the senses, harmonizing with the design, stories, and traditions of the product. In order to create such high-value-added manufacturing, we will contribute to making the Seiko Group's products even stronger by developing the basic and production technologies expressed by the words "Craftsmanship, Miniaturization, and Efficiency."

Over the course of the Seiko Group’s history, we have acquired new technologies alongside the progress of the age, in line with our founder’s spirit of "Always one step ahead of the rest." By flexibly combining our group's sensing, mechatronics, and other technologies with new challenges confronting society, such as decarbonization and a shrinking working population, we will contribute to the development of the wellness domain (sports, healthcare, and medicine) and the resolution of social and environmental issues.

Seiko Future Creation’s Strengths in Developing Technology

Advanced Basic Technologies

We possess the basic technology (development of differentiating materials, ultra-compact devices, etc.) and production technology (microprocessing technology, utilization of AI/3D vision, etc.) that support the Seiko Group's high-value-added manufacturing.

Leading Edge Technology

We develop new technologies that flexibly combine digital technologies in fields such as sensing, mechatronics, and information systems, and use these to contribute to the resolution of social issues.

History and Technological Wisdom

We have cultivated a strong technological background through many years of watch development and manufacturing, while also responding to the times and continually developing while constantly acquiring new technologies.

FA Systems Business

Seiko Future Creation's factory automation (FA) systems business proposes the automation of customers' manufacturing processes using the "Craftsmanship, Miniaturization, and Efficiency" production technologies we have cultivated through the facility development of watches and other precision equipment. With experience in automating manufacturing processes for many industries and products, we understand our customers' needs and provide them with more efficient facilities for parts supply, assembly, inspection processes, and so on.

Strengths of Seiko Future Creation's FA Systems

"Craftsmanship, Miniaturization, and Efficiency" Technologies

We create new value with "Craftsmanship, Miniaturization, and Efficiency" technologies cultivated through our experience in cutting-edge FA equipment, industrial mechatronic products, and watch mass-production facilities. We propose optimal facilities and solutions to enhance your manufacturing capabilities.

- Material handling of precision parts (supply)

- High-precision positioning and assembly

- High-speed positioning and assembly

- High-reliability inspections (image processing technology)

High Quality FA Systems

We can offer highly reliable FA systems because we ourselves are a manufacturer with internal manufacturing sites. As a manufacturer, we have developed our own FA systems and worked tirelessly to maintain and improve our technological capabilities. We can provide high-quality FA systems backed by the planning and proposal skills of design personnel with a thorough knowledge of manufacturing sites.

One-Stop Implementation

The process from design to implementation of FA systems can be provided as one-stop service. We can quickly handle a wide range of customer needs by carrying out all processes internally, including concept proposal, detailed design, manufacturing and procurement, assembly coordination, delivery and installation, and start-up.

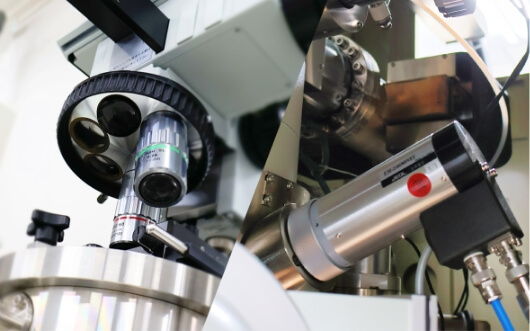

Analysis and Microprocessing Services Business

Seiko Future Creation offers commissioned instrumental analysis and processing services, including various types of Instrumental analysis, FIB microprocessing, and FIB circuit modification, and wiring correction, for the development of new products and technologies, as well as for quality improvement. We contribute to maintaining quality and reliability, and improving value as a technology brand, by identifying and resolving technical issues that arise in R&D, manufacturing, quality assurance, and other fields.

In FY2021, we introduced cutting-edge thermal analysis equipment, and in FY2022, we introduced a focused ion beam-scanning electron microscope(FIB-SEM) device with multiple functions, including SEM observation. We provide backup for resolving technological issues with our high expertise and analytical capabilities, from high-precision microprocessing to various observation/analysis techniques and technical consulting.

Seiko Future Creation’s Strengths in Analysis and Microprocessing Services

From Microprocessing to Various Analysis Techniques

We offer a wide range of technologies, from microprocessing to analysis (surface and cross-sectional analysis, morphology observation, thermal analysis, etc.), that can be applied in various industries and fields.

Customer Dialogue

We emphasize dialogue with customers to ensure we thoroughly understand the status of the issues they bring to us. Leveraging the experiences and successes in analysis that have supported the Seiko Group's manufacturing, we contribute to resolving issues concerning development, manufacturing sites, and quality assurance with our high level of expertise and technological capabilities.

Wide Range of Applications

We have extensive experience of microprocessing and analysis in a wide range of fields, from semiconductors and electronic components to automobiles, energy, metals, glass and ceramic materials, and food products. These support a wide range of applications, including technical assistance for failure analysis, development efficiency (analysis of other companies' products, evaluation of prototypes, etc.), acceptance inspections (material components, film thickness, etc.), and research related to patents and regulations.

Our Analysis and Microprocessing Services Cover Cases Like These

Examples of Research and Development Issues

- Understanding the properties and performance of materials during the development and material selection processes [Thermal Analysis]

- Learning the details about the shape, properties, composition, and structure of a sample surface [Cross-sectional Analysis]

- Revising the circuitry of a semiconductor [Circuit Wiring Modification]

- Preparing a sample for TEM analysis [Microprocessing]

- Prototyping a microdevice without making a mold [Microprocessing]

- Simulating thermal degradation of resin [Thermal Analysis]

- Comparing the texture of chocolate using numerical values [Thermal Analysis]

Examples of

Manufacturing Issues

- Understanding the properties and performance of materials for component selection and acceptance inspections [Thermal Analysis]

- Understanding the properties of materials in order to understand conditions in the manufacturing process [Thermal Analysis]

- Identifying the source of foreign matter in the manufacturing process

[Surface Analysis/Composition Analysis] - Analyzing the cause of poor solder mounting [Cross-sectional Analysis]

- Observing the electrode film cross-section of an electronic device [Cross-sectional Analysis]

- Carrying out periodic data collection of products [Surface Analysis and Composition Analysis]

Examples of Quality Assurance Issues

- Identifying the causes of problems in the market (smoke, abnormal heat generation, etc.) [Surface Analysis and Composition Analysis]

- Learning the causes of metal corrosion in the market [Cross-sectional Analysis]

- Checking defects and anomalies inside a semiconductor [Cross-sectional Analysis]

- Learning the cause of discoloration of connector pins [Cross-sectional Analysis]

- Observing the layer structure of plating as part of an acceptance inspection [Cross-sectional Analysis]

- Analyzing and evaluating controlled substances that are being used, in order to comply with RoHS regulations [Composition Analysis]